Nova Uscător Rotativ Universal SPB-UNI Cereale Paie Lucerna sušara za zitarice

Ako odlučite kupiti opremu po niskoj cijeni, provjerite da li vi komunicirate sa stvarnim prodavateljem. Saznajte što više informacija o vlasniku opreme. Jedan od načina prijevare je da se predstave kao prava tvrtka. U slučaju sumnje, obavijestite nas o tome radi dodatne kontrole, putem obrasca za povratne informacije.

Prije nego što odlučite izvršiti kupnju, pažljivo pregledajte nekoliko prodajnih ponuda kako biste razumjeli prosječnu vrijednosti odabranog modela opreme. Ako je cijena ponude koju vam se sviđa mnogo niža od sličnih ponuda, razmislite o tome. Značajna razlika u cijeni može ukazivati na skrivene nedostatke ili pokušaj prodavača da počini prijevaru.

Nemojte kupovati proizvode čija je cijena previše različita od prosječne cijene slične opreme.

Nemojte davati suglasnost na sumnjive zaloge i plaćanje robe unaprijed. U slučaju sumnje, nemojte se bojati pojasniti pojedinosti, zatražiti dodatne fotografije i dokumente za opremu, provjerite autentičnost dokumenata i postavljajte pitanja.

Najčešći tip prijevare. Nepošteni prodavatelji mogu zatražiti određeni iznos predujma kako bi "zarezervirali" vaše pravo na kupnju opreme. Dakle, prevaranti mogu prikupiti veliki iznos i nestati, i više se ne pojavljivati.

- Prijenos pretplate na karticu

- Nemojte plaćati unaprijed bez izdavanja dokumenata koji potvrđuju postupak prijenosa novca, ako vam je tijekom komuniciranja prodavatelj postao sumljiv.

- Prijenos na račun "povjerenika"

- Takav zahtjev treba biti alarmantan, najvjerojatnije komunicirate s prevarantom.

- Prijenos na račun tvrtke s sličnim imenom

- Budite oprezni, prevaranti se mogu prikriti iza poznatih tvrtki, neznatno mijenjajući njihov naziv. Nemojte prenositi sredstva ako vam je naziv tvrtke sumnjiv.

- Zamjena vlastitih podataka u fakturi stvarne tvrtke

- Prije prijenosa, provjerite jesu li navedeni detaljie ispravni i odnose li se na navedenu tvrtku.

Kontakti prodavatelja

Rumunjska

Rumunjska

Drying Capacity:

? Grains: 3,000 – 25,000 kg/h

? Straw / Alfalfa: 1,000 – 3,500 kg/h

? Sawdust / Manure: 600 – 3,500 kg/h

Over 25 Years of Experience | 24-Month Warranty

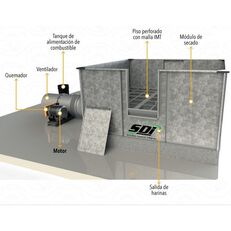

Universal Rotary Dryer SPB-UNI Standard – Performance and Versatility

The SPB-UNI Standard Universal Rotary Dryer is the ideal solution for efficient drying of raw materials used in briquetting, pelletizing, and granulation processes.

It ensures a uniform, rapid drying process across a wide range of materials, including:

Straw

Alfalfa

Biogas digestate

Fermented manure

Sawdust

Grains

Sand

Other moisture-rich biomass materials

✔️ Perfect for producing:

✅ Briquettes ✅ Pellets ✅ Granules (including organic fertilizer granules)

Designed for maximum efficiency, the SPB-5, SPB-10, SPB-20, SPB-30, SPB-30+-UNI Standard reduces the moisture content of raw materials, preparing them for optimal downstream processing.

It integrates seamlessly into briquetting, pelletizing, and granulation lines, providing high-capacity and stable performance.

Technical Specifications

Grains: input moisture 24% → output 14%, capacity up to 3,000 kg/h (depending on material)

Sawdust: input 50% → output 14%, capacity up to 600 kg/h

Straw: input 24% → output 14%, capacity up to 1,000 kg/h

Fermented manure: input 40–45% → output 14%, capacity up to 600 kg/h

Thermal power (heat generator): 300 kW – 2 MW

Fuel type: biomass – briquettes, straw pellets, sawdust, sunflower husk pellets, wood chips, agro-pellets

Total installed electrical power: 20–75 kW

Power supply: 400V, 3-phase, 24V/230V coils ±5%, 50 Hz

Weight: approx. 5,500 kg

Dimensions & configuration: customizable depending on plant layout and requirements

Technology year: 2025

Operating Principle

Industrial solid-fuel thermal unit with pyrolysis and hot air generator, built from stainless steel and fireclay for high-temperature resistance.

Cyclone separators for sparks and dust, including an electrostatic spark arrestor.

Automated feed hopper (1.6–3 m³) for raw materials such as pellets, sawdust briquettes, or wood chips.

Triple-chamber rotary drum with serpentine design for efficient heat exchange.

Fan and cyclone with rotary discharge valve for material separation.

Control panel with PLC (Siemens/Eaton) for automatic operation based on moisture readings.

Two homogenizing hoppers for wet material, 4.2 m³ each.

Drying Process:

Hot air flows through the three-stage serpentine rotary drum, where the wet material continuously mixes and loses moisture.

The dried material exits through the cyclone’s rotary valve, while humid air is exhausted through the ventilation system.

Complete SPB5-UNI Standard Universal Rotary Dryer Configuration

Industrial solid-fuel heating system with pyrolysis and hot air generator (KDV300-kDV2500)

2.4 m³ fuel storage tank

Emergency flue damper

Dust and impurity separator with cyclone

Electrostatic spark and dust separator

Storage silo A – 4.2 m³

Storage silo B – 4.2 m³

Walkway structure

Horizontal collection conveyor

Screw conveyor feeding the dryer

Raw material dosing valve

Triple-chamber drying cylinder

Drum support frame

Exhaust fan

Interconnecting pipelines

Cyclone separator

Rotary material distributor

Discharge screw conveyor

Air and steam system

Flue gas exhaust

Automatic ash removal system

Electrical control panel with PLC touchscreen and remote monitoring access

Automation & Control System

The entire system is managed via a centralized PLC touchscreen panel, enabling automatic regulation of all drying parameters.

Once the desired settings are applied, the SPB-UNI Standard can operate fully automatically, with minimal operator supervision.

All electrical components comply with EU industrial safety and performance standards.

Optional Accessories

In-line moisture sensors (input and output)

Compact mobile version of the SPB-UNI Standard universal rotary dryer

Conclusion

The SPB-UNI Standard Universal Rotary Dryer is a versatile, high-efficiency drying solution for a wide range of biomass materials.

It enables cost-effective and sustainable processing, turning agricultural residues into eco-friendly fuel or organic granules, with optimized yield, energy use, and operational reliability.